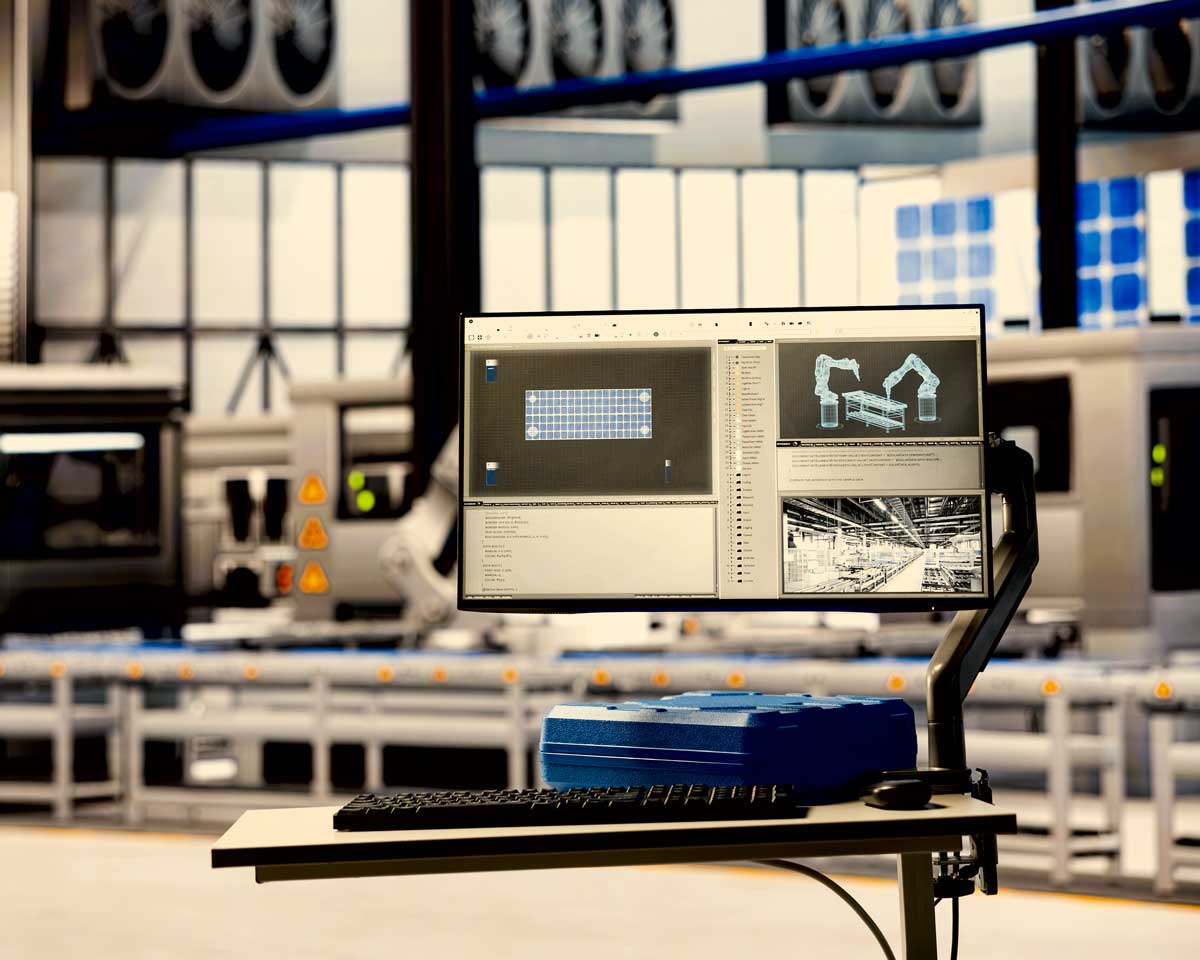

Robotic welding

for industrial series

Repeatable welds, measurable quality, full parameter traceability (QMOS)

Repeatability

Dimensional + dye penetrant checks

Traceability (QMOS)

Why Cobotec

Our engineers assess every project in detail, working with you from the moment your 2D drawing is received to define tolerances, control points and procedures. Whether your operations are based in Wallonia, Brussels or abroad, we provide a fully industrialised solution—from initial study to full-scale series production—by configuring each robotic cell to match your required volumes.

Rigor by design

Automated torch path removes operator variability and stabilizes cord profile over the series.

Unit-cost control

Faster cycles and multi-cell supervision translate directly into a lower unit cost for your parts.

Documented quality

Welding parameters are logged; QMOS on request for qualified procedures and audits.

What we do

Materials

Carbon steel & stainless steel (aluminum: equipment ready, industrialization not yet released).

Input needed to quote

A 2D drawing is sufficient to evaluate manufacturability and checks.

Volume sweet spot

Cost-effective from ~100 pcs upward, depending on geometry; replication by multiple cells if needed.

Quality checks (in-house)

Dimensional + dye penetrant; X-ray on request via certified partners.

Finishing

We do not deliver cosmetic grinding at this stage; downstream paint or other surface treatments can be coordinated.

Typical parts & industries

Applications

Frames & brackets, housings and enclosures, fluid-handling subassemblies, fixtures, sheet-metal weldments.

Industries

Machinery OEMs, medical & pharma equipment, automotive sub-suppliers, energy, EV charging, food equipment.

Process

With fully automated systems, we provide measurable results: repeatability, strict process control, and built-in QM-OS traceability. You bring us your parts; we ensure documented quality, consistent weld seams, and optimized cost per unit.

Send drawing + requirements

— tolerances, checks, environment of use.

Welding study / procedure

— torch path, parameters; QMOS if required.

Pilot run

— validate repeatability and checks on a small lot.

Series production

— robotic welding, logged parameters.

Inspection & records

— dimensional + penetrant; optional X-ray via partner.

Dispatch

— packaging standard; specific kitting on request.

What’s included

Included

- Robotic welding

- Dimensional & dye penetrant checks

- Parameter logging

- Procedure documentation (when applicable)

Optional

- Cutting

- Bending

- Drilling

- Surface treatments

- X-ray — coordinated with approved partners

Not included

- Cosmetic grinding

- Branded packaging (available on request if required by your line)

Can we make your part ?

Parameter |

Cobotec practice |

|---|---|

| Materials | Steel, stainless (Al: not yet released to production) |

| Minimum input | 2D drawing (PDF/DWG/PNG) with notes/tolerances |

| Checks | Dimensional + dye penetrant (X-ray via partner) |

| Series economics | Typically competitive from ~100 pcs |

| Lead times | Depend on geometry, quantity, and line load |

By choosing Cobotec, you embrace a true industrial logic, where repeatability is no longer a matter of chance but the result of a fully controlled process.

We support production runs starting from a few dozen units, helping your facility—whether located in Wallonia or abroad—achieve lasting performance.

Every weld counts, and every batch deserves nothing less than excellence.

Upload a 2D drawing

Still any question ?

Do you need a 3D model?

A 2D drawing is sufficient to assess feasibility and define checks.

How do you guarantee repeatability?

We lock and monitor welding parameters on the cell and validate cord geometry on a pilot run before scaling.

Can you certify procedures (QMOS/WPQR)?

Yes—on request. We can prepare and document qualified procedures when your application or audit requires it.

What about large volumes?

For very large runs, we replicate cells to scale throughput. If you’re in millions of parts/year, a dedicated line may be more economical; we’ll advise.

Do you handle surface finishing or painting?

We can coordinate these with partners when needed; baseline delivery excludes cosmetic grinding and special packaging.

Ready for a pilot run?

A 2D drawing is all we need to start the assessment.

Follow us

COBOTEC — Rue Julien Jacobs 1b — 4367 Crisnée — Belgique